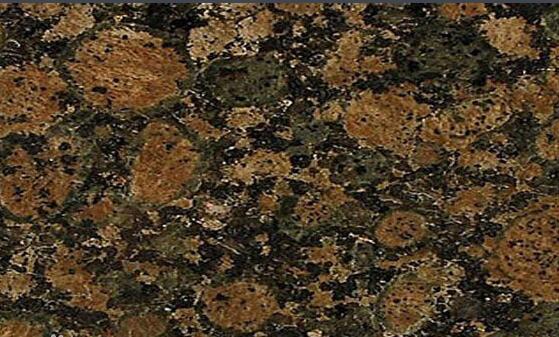

Granite produced in Finland, also known as brown diamond, has a dense structure, hard texture, good acid and alkali resistance, and good weather resistance, and can be used outdoors for a long time. The characteristics and advantages of granite also include high load-bearing capacity, compressive capacity and good grinding ductility. It is easy to cut and shape, and can create thin plates and large plates. It can be made into various surface effects-polishing, matte, fine Grinding, burning, water jetting and sandblasting etc. It is generally used on the ground, steps, bases, steps, cornices, etc., and is mostly used for indoor and outdoor walls, floors, and column decorations.

Origin:

Finland

Background color:

Brown

Texture color:

Coffee

Flower style:

Big flower

Density:

(B.D):g/cm: 2.64

Water absorption:

0.2%

Fields of use:

Indoor ground, interior walls, stage face plate, outdoor metope, ground outdoor, cylinder, staircase, sculpture

Processing technology introduction:

Use a 90 steel angle ruler with an inner angle verticality tolerance of 0.13mm and an inner angle side length of 500mmx400mm. Place the short side of the square against the short side of the board and the long side of the square against the long side of the board Use a feeler gauge or a vernier caliper to measure the maximum gap between the length of the board and the long side of the square. When the length of the plate is less than or equal to 500mm, any pair of diagonal corners of the plate can be measured; when the long side of the plate is greater than 500mm, the four corners of the plate can be measured. The measured value of the maximum gap indicates that the measured value of the angular tolerance of the plate is accurate to 0.1mm.

①Pattern color tone Put the plywood board and the inspection board flat on the ground and stand at a distance of 1.5m from the board for visual inspection.

②Artificial chisel marks Place the board flat on the ground at a distance of 1.5m from the board for visual inspection.

③Number of color lines Measure the number of color lines visually.

④ Chipping and chipping Use a vernier caliper to measure the length, width, and height of the defect and visually measure the number of chippings.

⑤ Steps Use a vernier caliper to measure the height of the steps and measure the maximum value as the height of the steps.

⑥ Cracks Visible cracks are visually detected. Hidden cracks are determined by hammering, that is, hitting the plate with a metal hammer. The sound is usually muted to identify whether there are cracks.

⑦Stains Use a vernier caliper to measure the size of the stains and visually assess the number of stains.

Marble is a relatively soft stone. On the Mohs hardness scale, the MOHS marble grade is about 3 and the highest is 10. Marble, like teeth, is made of calcium. If you bite on something too hard, your teeth will break. If you eat too much sugar, your teeth will perforate. The same goes for stone. If the reagents used on the surface of the stone are not suitable, the stone will begin to rot and form holes. The following is the famous Mohs hardness scale MOHS. This standard was developed in the early nineteenth century and it helps to identify the strength and hardness of the stone used so that corresponding measures can be taken when applying it. For example, stones with lower hardness need to be mopped more frequently with softer agents.

1. Talc 2. Gypsum 3. Calcite Most marble 4. Fluorite 5. Apatite 6. Feldspar granite 7. Quartz granite 8. Topaz 9. Corundum 10. Diamond Mohs hardness scale is used to measure the resistance of stone degree of grinding. Stone is scratched when sediment or grit is harder than the stone surface. For example hard plastic has a hardness rating of about 2.0 and it will not scratch calcite (marble) which is rated 3. Sand with a hardness of 6 will scratch calcite of grade 3 but will not scratch quartz or granite of grade 7. The higher the hardness level, the more wear-resistant it is. Foreign deposits in buildings have hardness measurements of 3.0 to 7.0