The stone slab scanner is currently a popular stone slab solution, and it is also a product regarded as a revolutionary technology in the stone industry. However, most people who work in the stone industry do not know this instrument very well. Today, we will introduce the stone scanner.

The stone scanner is a device that collects detailed photos of stone slabs by scanning.

This machine is installed behind the marble polishing machine. When the stone slab is polished, the scanning equipment will use the roller linkage to judge the trajectory of the slab. When the stone slab passes the equipment, the camera is triggered to automatically scan and collect. The installation and implementation of this equipment are simple and quick and does not affect the normal production of the enterprise.

The stone scanner generally includes two parts, the acquisition part, and the data processing part. The collection part is composed of high-definition lens, color camera, line array light source, etc., to collect the image of the stone slab. The data processing part is composed of a computer, a display screen, and an image capture card to perform equipment control operations and database processing of the stone slab.

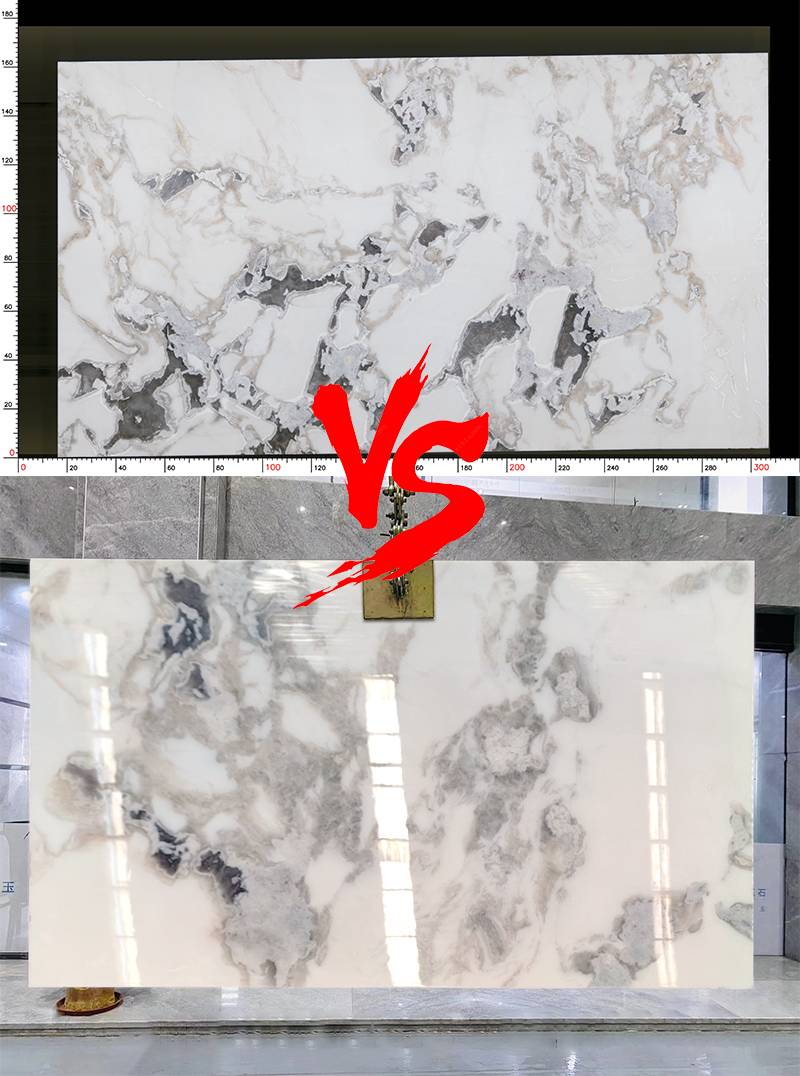

Let’s compare the stone photos taken by the camera and the stone photos scanned by the stone scanner.

From the photos, we can see that when the stone scanner collects the slab picture, it also obtains the length and width of the slab at the same time, and each slab picture corresponds to a unique QR code ID, which corresponds to a unique slab. We can draw the conclusion that these stone slabs can realize digital information management in the future.

The digitalization of each industry can bring about disruptive changes in the industrial chain structure, business model, corporate marketing management, production and manufacturing, and the stone industry is no exception.

The previous stone warehouse management methods have some problems, such as statistical difficulties, low accuracy, low efficiency, and so on.

The digitization of stone slabs provides the possibility for intelligent stone storage. Combining the ERP system with a mobile phone can manage everything, for example, all inventory information is clear, easy to check inventory, and manage pricing. Sweep the QR code label on the stone slab goods, and the goods storage or delivery work is completed.

The stone-related work is freed from the heavy registration, billing, and accounting work, and the focus of work can be shifted to in-depth information utilization and processing. Through data analysis, we can accurately grasp the dynamics of production, processing and sales, and reduce the inventory of goods, and business operations will be more predictable.

Throughout the development of stone processing, the processing equipment of each link is becoming more sophisticated and automated, and innovation has never stopped. As the slabs are digitized, the intelligent processing of stone slabs is finally realized.

Through the most advanced stone scanning machine, the big slab is scanned and imaged by an intelligent scanner, the stone big slab picture is imported into the stone wizard to pre-cut the big slab layout, and the resulting cutting plan is imported into the cutting machine to automatically cut the big slab, The stone processing will become very easy.

Intelligent processing can complete more complex, high-precision, multi-process operations, and at the same time effectively increase production capacity and improve stone utilization, which will definitely become the development direction of the stone industry.

GOLDTOP Stone have a online stone slabs store, if you have any inquiry pls contact us.